Omni-directional wheels are unique as they are able to roll freely in two directions. It has rollers mounted along its circumstance . It can either roll like a normal wheel or roll sideway using the rollers. Its rubber rollers offers great gripping. It is suited for use in robotic, trolleys, transfer conveyor, shipping carts, luggage.

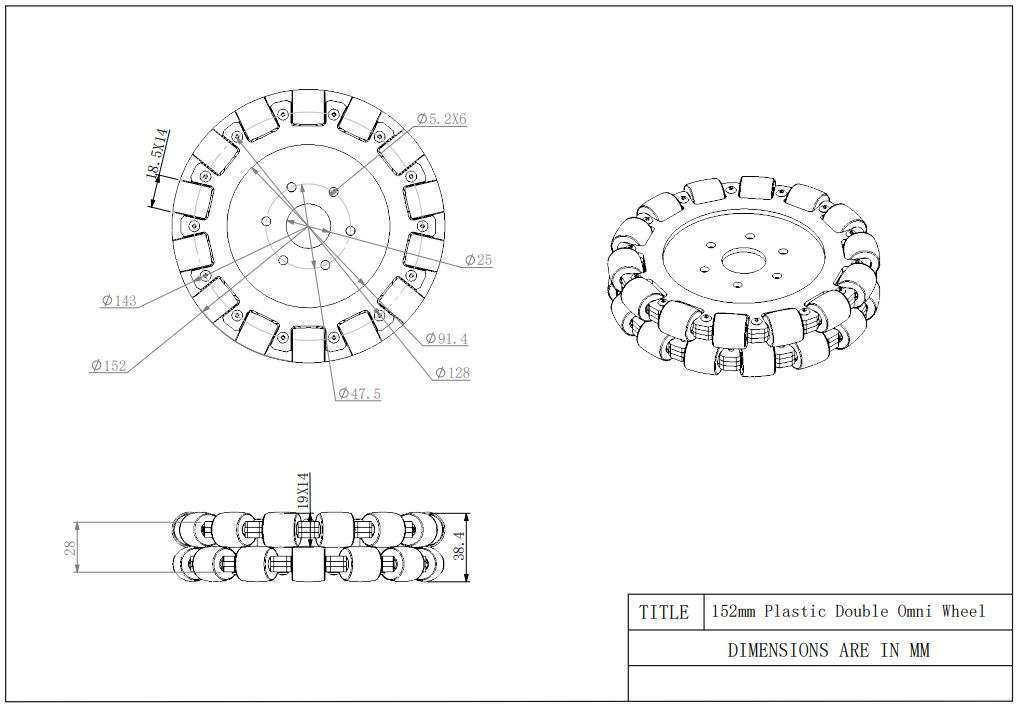

152mm double plate aluminium omni wheel

Specification:

Diameter:152mm

Axial width:29mm

Number of plates:2

Number of rollers:28

Body material:Aluminium alloy

Roller material:Rubber

Roller bearing:Brass tube

Roller diameter:19mm

New weight:630g

Load capacity:20kg

Benefits:

•Omni direction movement and rotation

•Easily direction control and tracking

•Make turning fast

•Precision placement— no offset movement

•Require no lubrication or field maintenance.

•Unique fixed orientation

•Simple & stable mounting options

•Direct tracking & directional control

•Superior load stability

Applications:

•Material handing equipment

•Shopping carts and luggage

•Freezer duty torlleys and carts

•Conveyor transfers pipe rollers

and other inverted applications

•Ball transfer table alternatives

•Robotics

•Mobile furniture

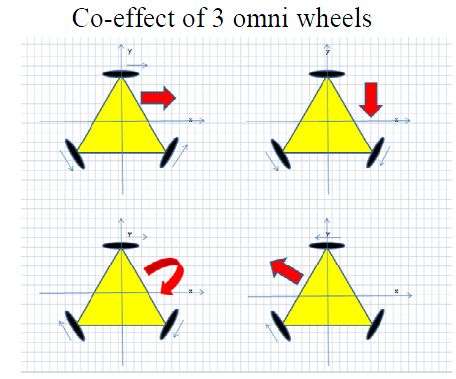

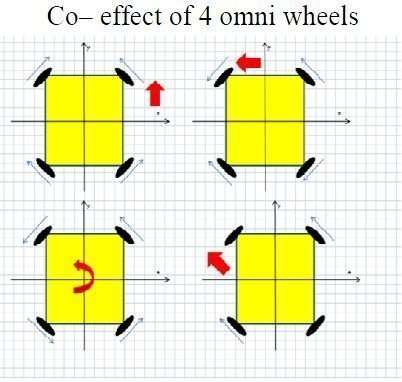

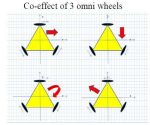

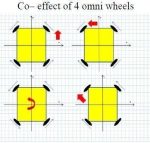

Omni-directional wheels are unique as they are able to roll freely in two directions .It can ether roll like a normal wheel or roll laterally using the wheels along its circumference.Omni-direction wheels allow a robot to convert from a non-holonomic to a holonomic robot.A non-holonomic robot that uses normal wheels has only 2 out of 3 controllable degrees-of-freedom which are,moving forward/backwards and rotation.Not being able to move side ways makes a robot slower and less efficient in reaching its given goal. The holonomic omni-directional wheels are able to overcome this problem,as it it a highly maneuverable.Unlike normal non-holonomic robot,the holonomic omni-directional robot can move in an arbitrary direction continuously without changing the direction of the wheels.It can move back and forth,slidewaysmand rotates at the same position.

Single plate or double plate:

Single plate omni wheels have a single plate of passive rollers. Dual plate omni wheels have two plates of passive rollers that are rotated slightly with respect to each other. Dual plate omni wheels have the advantage of no “dead area” between rollers. That is, when a dual plate omni wheel is rolling, the two plates continuously take turns bearing the load, resulting in smoother motion when compared to single plate omni wheels.

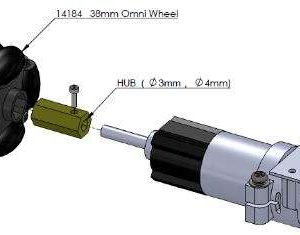

We also have the hub used to connected a omni wheel to a motor.While a omni wheel is play its part as a drive wheel. Most of the case, omni wheels can be used as a drive wheel in a mobile robot or a small transfer vehicle.